In the fiercely competitive coffee market, coffee packaging pouches are more than just product packaging; they also serve as a vehicle for brand image, quality assurance, and user experience. A high-quality packaging pouch effectively isolates oxygen, moisture, light, and other factors that can cause oxidation and deterioration of coffee beans or grounds, thereby extending the flavor stability of coffee. Furthermore, for buyers or brands engaged in coffee packaging, choosing the right coffee packaging supplier is crucial.

A reliable supplier can ensure food safety standards for packaging materials, a stable supply, and high-quality ongoing service. In this article, we will explore in detail the importance of coffee packaging pouches, key design and material technical considerations, supply chain selection criteria, environmental trends, and packaging innovation cases. This will provide a professional perspective on how to select the right coffee packaging supplier and enhance the competitiveness of your coffee products.

Section 1: The Function and Importance of Coffee Packaging Pouches

In the coffee industry chain, packaging carries responsibilities far beyond surface decoration. The main functions of coffee packaging pouches include isolation, protection, label communication, ease of use, and brand communication.

Isolation and Protection

Coffee is very susceptible to oxidation, moisture, and smell absorption. A good packaging pouch has to have extremely low oxygen and water vapor transmission properties. High-performance multi-layer composite packs in some experiments had over 80% aroma retention after storage for six months. Poor packaging may accelerate aroma evaporation and flavor loss significantly impacting the consumer experience.

Information Delivery

The coffee packaging pouch is a bearer of labels, brand marks, product traceability, instructions, barcodes, and legal warnings. Brand images and key specifications can be prominently showcased on the coffee packaging pouch through high-precision printing, thermal transfer printing, UV printing, and other technology, which assists in establishing customer confidence. Multi-color printing, flexographic printing, and anti-counterfeit elements are normally offered by premium-quality coffee packaging providers.

Ease of Use

As the market evolves, features such as zippered stand-up pouches, one-way degassing valves, tear-off notches, and portioning bags are becoming increasingly popular. Consumers are seeking pouches that are portable, resealable, and easy to use. Excellent coffee packaging suppliers offer these innovative designs and rigorously control sealing performance and packaging strength during production.

Brand Communication

From product placement and display to consumer unboxing and social media posting, packaging plays a crucial role in creating a compelling first impression. A beautifully designed coffee packaging pouch stands out on the shelf, enhancing brand recognition and appeal. A quality coffee packaging supplier will provide clients with creative structural and process design support, transforming the packaging into a true marketing tool.

Through the four functions described above, we can see that the coffee packaging pouch is more than just an ordinary packaging container; it is a comprehensive reflection of the coffee brand’s value, product quality, and user experience.

Section 2: Material and Structure Design Key Points

Material and structure design are crucial elements in creating a high-performance coffee packaging pouch. Material structure selection and lamination procedure are critical elements in measuring your coffee packaging supplier’s ability.

Composite Layer Structure

High-quality coffee packet packaging most commonly uses a multi-layered composite material structure, i.e., PET/AL/NY/PE, PET/EVOH/PE, or CPP/NY/PET. Each layer of material has a distinct function:

- The outside PET layer provides strength and resistance to tears.

- Al (metallic foil) or EVOH provides oxygen barrier properties.

- NY (nylon) improves puncture resistance.

- The inside PE or CPP layer offers heat sealing and food safety.

The rate of oxygen transmission in a high-performance bag should generally be less than 1 cc/m²·day or even less. Some of the high-end coffee pouch packaging available in the market is documented to be as low as 0.3 cc/m²·day.

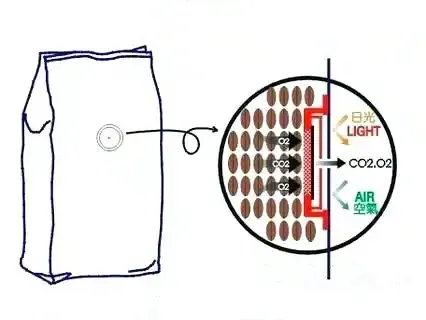

Valves, Sealing Strips, and Seal Design

One-way degassing valve bags are very common, especially for storing recently roasted coffee beans. The one-way valve expels CO₂, backflows oxygen, and prevents pressure differentials in the bag without affecting flavor. A good coffee packaging supplier will ensure that the valve is securely bonded, the valve material does not age, and the sealing capacity remains stable.

Also, zip locks or resealables require tight controls of parameters such as heat seal temperature, pressure sensitivity, and edge width. Structural design also requires attention to features such as tear-off edge, security seal, and bottom support structure (square or 3D bottom).

Printing Process and Surface Treatment

Luxury coffee packaging pouches mostly utilize surface treatments such as flexographic printing, UV varnishing, and matte or glossy coatings. Print clarity and color precision are crucial for brands. A reputable coffee packaging supplier will have the latest printing machinery, color management systems, and sample calibration processes to ensure color differences are within tolerance (e.g., ΔE ≤ 2).

Safety and Regulatory Requirements

As a packaging for food or beverages, the materials used for coffee packaging pouches must be compliant with food contact materials regulation standards (e.g., FDA, EU 10/2011, GB 4806, etc.). The construction should not utilize heavy metals, plasticizers, and non-food-grade adhesives. During selecting the suppliers, prefer those with the respective certifications (e.g., FDA approvals, food-grade material test reports, and GMP production line certifications).

With solid structural design and material selection, the Coffee Packaging Pouch can actually meet a set of needs such as oxygen isolation, moisture resistance, safety, and aesthetics.

Section 3: Industry Trends and Innovative Packaging Case Studies

With market and technological evolution, coffee packaging pouches are experiencing significant developments in materials, environmental friendliness, and functional innovation. Several trends and typical cases are listed below.

Degradable and Recyclable Material Trends

To address environmental concerns, more brands and suppliers are exploring solutions such as PLA, bio-based films, and recyclable single-material structures. Some experimental results show that bags using PLA-coated PE can degrade at room temperature within 18 months in specific environments.

However, currently, degradable materials still face technical challenges in terms of barrier properties, heat seal strength, and impermeability. In the future, established coffee packaging suppliers may offer mixed recyclable structures (such as single PET recyclable structures) or degradable composite film solutions.

Smart/Interactive Packaging

In recent years, some brands have integrated QR codes, NFC chips, and augmented reality content into coffee packaging pouches, allowing consumers to scan the code to access traceability information, roast date, flavor recommendations, and more. For example, a high-end coffee brand features a dynamic QR code on its packaging. Scanning the code allows consumers to watch videos about coffee farms and participate in the brand’s community. This packaging format not only increases consumer stickiness but also strengthens the brand’s storytelling.

Small Packaging/Pouch Design

To meet the trend of “brew and drink” and “single-serve consumption,” some brands offer 10–20g small sachets or integrated daily capsule packaging. Easy-tear pouches, individual zipper bags, and fusion packaging are increasingly popular among consumers. A suitable coffee packaging supplier will offer these small packaging solutions and optimize sealing and flavor protection.

Mixed Materials and Transparent Window Design

Some pouch designs incorporate transparent windows or semi-transparent nodes while maintaining barrier properties, allowing consumers to directly see the product. This design enhances trust and increases purchase desire. However, the window must be strategically positioned to prevent light and oxygen intrusion. A good coffee packaging supplier will simulate light and oxygen diffusion models during the design phase to ensure that the window does not conflict with the overall packaging performance.

Case Study

A renowned international coffee brand launched its “Single Origin” series. The packaging features an aluminum foil composite structure, a one-way valve, a self-supporting base, a matte UV coating, and a QR code on the back that points to a video showcasing the origin of the coffee. After the series’ launch, the packaging became a popular photo-sharing platform for consumers, significantly boosting brand awareness. The supplier behind this product is a coffee packaging supplier known for its innovative capabilities and stringent quality control.

In summary, the industry trend for coffee packaging pouches is towards greener, smarter, and more convenient packaging. These development paths also place higher demands on coffee packaging suppliers’ R&D capabilities, material capabilities, and technological innovation.

FAQ

Q: What are the benefits of having a multi-layer composite Coffee Packaging Pouch?

A: A multi-layer composite construction can provide barrier, strength, and sealing functionality in layers. It offers increased oxygen transmission rates and water vapor barrier than single components, hence better protecting the coffee flavor.

Q: Are degradable materials applicable in Coffee Packaging Pouches?

A: Yes, but currently there are technical problems with biodegradable materials concerning barrier properties, heat sealing, and durability. If you do opt for these materials, you should use a qualified coffee packaging supplier and test extensively.

Q: How do you know whether or not a coffee packaging supplier is trustworthy?

A: On the basis of criteria such as food-grade certifications (e.g., FDA and GMP), production capacity, customized nature, level of quality control, rate of sample communicative response, and prior client case studies, an in-depth assessment can be done.

Q: How durable is a Coffee Packaging Pouch in long-distance shipping and export environments?

A: It must be sealed, waterproof, odor-resistant, and capable of withstanding structural stress under different temperatures, vibration, humidity, and long-distance transportation. The material characteristics and supply chain support of the supplier must be consistent. If you require more details on Coffee Packaging Pouch or how to choose a coffee package supplier, please feel free to ask me. I can provide you with more specific advice and industry solutions.