Pharma packaging is far from a simple container; it is the ultimate line of defense for drug safety, efficacy and patient trust. In the era of stricter global supervision, complicated supply chain and the threat of counterfeit drugs, excellent packaging design has become a crucial system engineering, which precisely balances legal compliance, physical protection and humanized experience.

The following is a practical guide provided by Meishida, a leading healthcare packaging company, which introduces the key points of core design for drug packaging.

Materials and structural design

- Transport reliability verification

The pressure resistance of packaging should be verified by ASTM standards (such as drop test and impact test) to confirm whether the big box design, small box design and inner support design of the product can meet the actual transportation road conditions and avoid damage of circulation links.

- Special environment adaptation

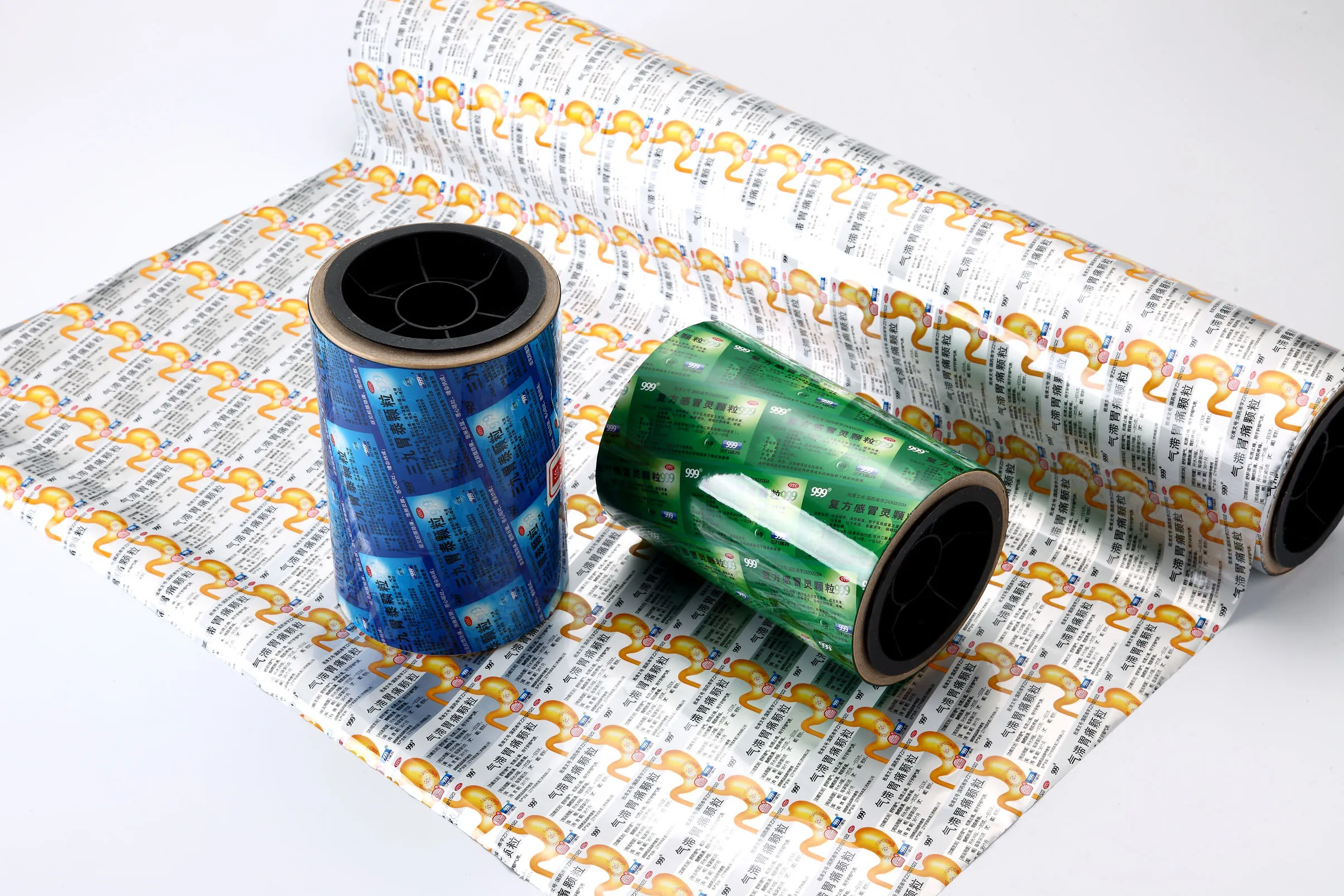

Frozen drugs should use low-temperature-resistant ink to prevent the label information from being blurred. Photosensitive drugs, on the other hand, rely on high-barrier light-proof materials (such as aluminum foil composite film).

Safety protection design

- Child-resistant packaging (CRP)

Mandatory requirements in Europe and America: the United States follows the PPPA Act and 16 CFR 1700.20, and the European Union follows the ISO 8317 standard. Packaging needs to ensure that children are difficult for children to open within a reasonable time, but adults have no difficulty in normal use.

- Anti-tampering and anti-counterfeiting technology

Tamper-proof: Tampering prevention means that once a drug is opened, it cannot be recovered and will be found. Tampering prevention is mainly designed by sealing labels, disposable tear films, etc. Although it is not mandatory in China, it is suggested to have a similar design from the perspective of the whole control chain of drugs, to facilitate the investigation and handling of subsequent complaints involving products.

Anti-counterfeiting refers to a means of confirming and identifying drugs as those produced by the authorized enterprise. Anti-counterfeiting measures are mainly through special ink (color change in case of chemical reagents), miniature text, etc., to deal with the risk of counterfeit drugs.

Compliance & Traceability

- The Global Passport

China enforces the drug traceability code (one thing, one code), while the European Union requires a unique identifier according to the FMD directive. The packaging label must be reserved, and the serialization code must be clear and readable.

- Informational Integrity

Labels should contain core data such as composition, batch number and expiration date, and the font size should comply with laws and regulations, ensuring that the information is accurate and easy to read.

User Experience Optimization

- Elderly-friendly design

Easy-to-open lid, large font label and clear medication instructions are adopted to significantly improve medication compliance and safety.

- Sustainability Imperative

Use degradable materials and do your duty to protect the environment.

Conclusion

The packaging of drugs is directly aimed at the end users. In the design, we should consider the protection of products, misuse by children, anti-counterfeiting and anti-tampering, integrity during storage, traceability of drugs and so on. At the same time, ensuring that the regulatory requirements of different markets are met is also an important link to strengthen the whole process control of drugs.

For enterprises, it is a strategic task to manage the packaging life cycle with forward-looking thinking and actively integrate innovative solutions to build trust, avoid risks, and achieve differentiation in the fierce market competition.

About Meishida

Meishida is a leading pharmaceutical packaging manufacturer, specializing in offering wholesale supplement packaging supply and custom supplement packaging solutions for global brands. We operate with internationally recognized safety standards and maintain rigorous production control to ensure consistent quality.

As a factory-direct partner in the supplement packaging industry, we deliver reliable materials, stable lead times, and packaging solutions tailored to real market needs.

Partner with Meishida, and you are provided:

✅Excellent quality

✅One-stop custom service

✅BRC, ISO, FDA certified products

✅Innovative technology support

✅Environmentally friendly philosophy

✅Quick expert team response