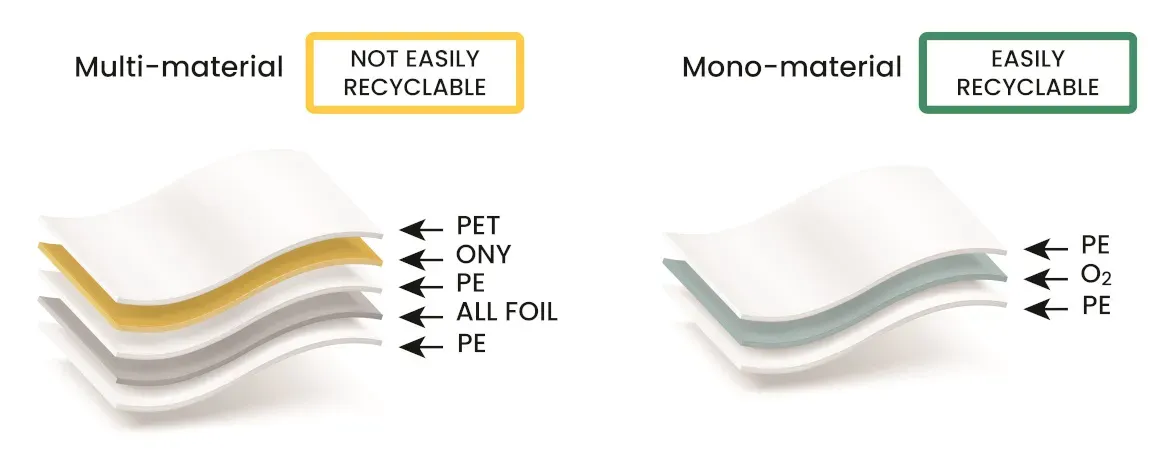

Brands and procurement teams are under pressure to make packaging more recyclable — but for liquids and semi-liquids, the choice is not purely environmental. Mono-material flexible packaging promises improved recyclability, yet it introduces engineering trade-offs that affect barrier performance, sealing reliability, and total cost.

In this guide, Meishida Packaging, a leading pharmaceutical packaging manufacturer, explains when mono-material can work, what to test, and how to brief suppliers so you don’t discover problems at scale.

Why Buyer is Talking About Mono-Material Flexible Packaging

Regulatory moves and retailer targets push brands toward recyclable formats. At the same time, the EU Packaging and Packaging Waste Regulation (PPWR) requires >80% recyclable packaging by 2030, accelerating mono-material adoption in Europe and influencing global standards. Liquid products are the highest-risk category for packaging failures: leaks, off-odors, and moisture/oxygen-driven spoilage quickly become customer complaints and recalls.

The core question for buyers: can a single-polymer system meet both recyclability goals and the functional needs of the product?

What “Mono-Material” Actually Means

“Mono-material” doesn’t necessarily mean a single layer. Common practical approaches include:

- All-PE laminates (coextruded PE / PE sealant layers) — most recycling systems accept PE.

- All-PP constructions — emerging for some hot-fill applications.

- PE + EVOH barrier co-extrusion where EVOH is sandwiched inside a PE matrix, but the outer and inner materials are PE-dominant to ease recycling streams (note: EVOH is not PE, so local recycling rules matter).

Important: marketing claims like “fully recyclable” only hold where local collection and reprocessing systems accept the polymer and the pouch format.

Suitability: When a Mono-Material Flexible Packaging Solution Makes Sense

Mono-material flexible packaging is most appropriate when:

- The SKU has a short to moderate shelf life (days → months, not years).

- The product is low in free oil or has manageable oil content.

- The product is refrigerated or distributed within controlled cold chains.

- The brand prioritizes end-of-life recyclability, and the target market has PE/PP recycling infrastructure.

- The SKU is high-turnover or limited-edition, where simpler recycling credentials deliver real consumer value.

Avoid mono approaches for long ambient shelf life, very oily sauces, or carbonated/fermenting liquids unless you have validated performance data.

Barrier Reality: Numbers Not Buzzwords

Engineers use metrics — not “high barrier.” For decisions, require supplier data:

- MVTR (g/m²∙24h) — moisture protection is often the primary need for biscuits, crackers and many snacks; for liquids, it still matters when headspace or hygroscopic ingredients exist.

- OTR (cm³/m²∙24h) — critical for oxidation-sensitive liquids (omega-rich drinks, dairy).

A mono PE pouch will typically have worse MVTR/OTR than a foil or VMPET laminate. If your shelf-life target cannot be met by the mono construction’s MVTR/OTR under real-world RH and temperature, do not proceed.

Seal Integrity and Leakage Risks: Critical Failure Points in Operational Quality Control

Mono structures change the thermal window for sealing. Key failure modes:

- Inadequate hot-tack at required line speeds → cold seals and leaks.

- Seal contamination (product in the seal area) causes weak joints.

- Spout integration: spout materials and welding method (ultrasonic vs heat) must be compatible with the mono film.

Require these tests before approval: seal strength (N/15mm), burst test, accelerated leak tests, and production speed trials on your actual filler. Pilot runs on the factory line are mandatory.

Spout Cap Material and Fitment Compatibility

If your product uses a spout pouch, verify whether the spout and cap are part of the recyclable stream. Many spouts are PP, while the pouch cap is PE — that combination can negate recyclability in practice. Options:

- Use PE spouts and caps so the entire fitment is mono-polymer.

- Confirm welding method and torque retention under vibration and temperature cycles.

- Get a full bag + spout lifecycle statement from the converter.

Supply Chain & Climate Considerations

EVOH barrier performance degrades at high humidity unless properly encapsulated. Seasonal variations, tropical markets, and long container voyages can expose mono builds to conditions that dramatically alter barrier behavior. Model real distribution profiles and test at elevated RH.

Cost & TCO: Mono-Material Flexible Packaging Is Not Always Cheaper

Mono materials can reduce end-of-life costs, but they may increase direct production expense (special co-extrusions) or indirect costs (higher scrap, more pilot runs, lower yields). Always evaluate Total Cost of Ownership:

TCO = Unit price + Scrap/rework + Expedited freight risk + MOQ carrying cost + Consumer returns

If mono increases scrap or returns, any sustainability benefit vanishes.

Practical Supplier Brief — What to Demand

When you approach converters, include this checklist:

- Provide batch-level MVTR/OTR for the finished pouch and test conditions (RH, T).

- Demonstrate seal-strength and burst data at your line speed and temperature.

- Supply pilot run on your filler or a validated OEM line with acceptance criteria.

- Confirm spout/cap polymer chemistry and recyclability claim scope.

- Show retention-sample policy and change-control agreement for material substitutions.

- Provide organoleptic tests and migration reports if the product is sensitive.

Final Thought

Adopting mono-material solutions is a systems decision — material science, filling equipment, logistics, and local recycling infrastructure must align. Treat mono-material flexible packaging projects as engineering programs: specify measurable targets, require pilot validation, and model TCO. Do so, and you can deliver recyclable packaging without compromising product integrity.

About Meishida

Meishida is reckoned as a leading pharmaceutical packaging manufacturer and actively proceeds to broaden our business scope in the flexible packaging industry. Now, apart from the pharmaceutical packaging, we are having our business in the Healthcare Packaging, Food Packaging, Cosmetic Packaging, Liquid Packaging, and Coffee Packaging

For years, we have worked closely with B2B customers to develop custom mono-material and multilayer liquid packaging solutions, aligning barrier performance, sealing reliability, and recyclability targets with real filling and distribution conditions. From specification definition to batch-level quality control, Meishida positions itself as a production partner rather than a trading supplier.